Engineering Services

Polyplas International’s technical services department is able to work in collaboration with partners around the world to offer the following range of engineering services to building services consultants, designers and engineers.

Installation Design

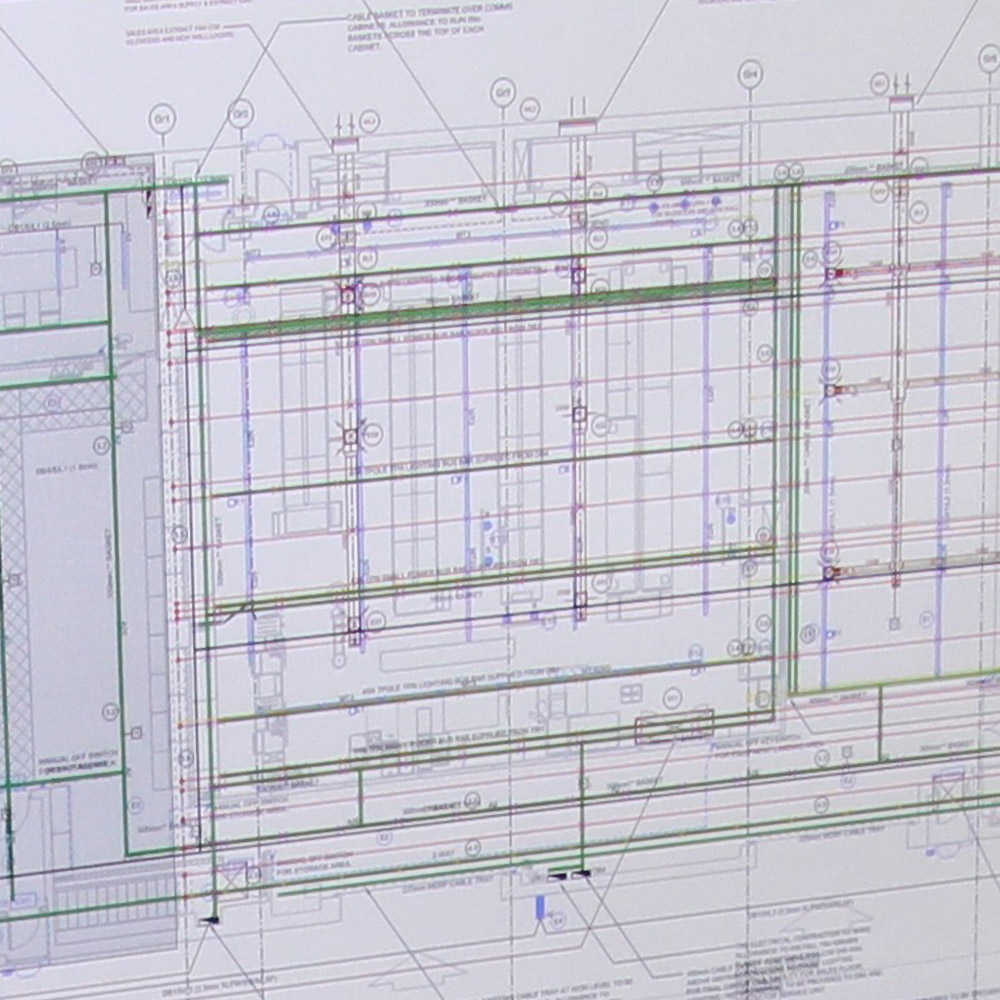

Polyplas International’s technical services team offers a full suspension system design service. Drawings can be submitted in either .dwg or .pdf file formats and are returned fully annotated and costed. Bespoke bracket design, and assistance with minimising suspension elements and cost can also be provided. In order to reduce programme time and installation costs further, Gripple Catenary Systems can be employed to span structural steels and suitable building components.

The installation design service provides the contractor with annotated drawings showing the location and length of each catenary wire to simplify the installation process.

Catenary Tension Analysis

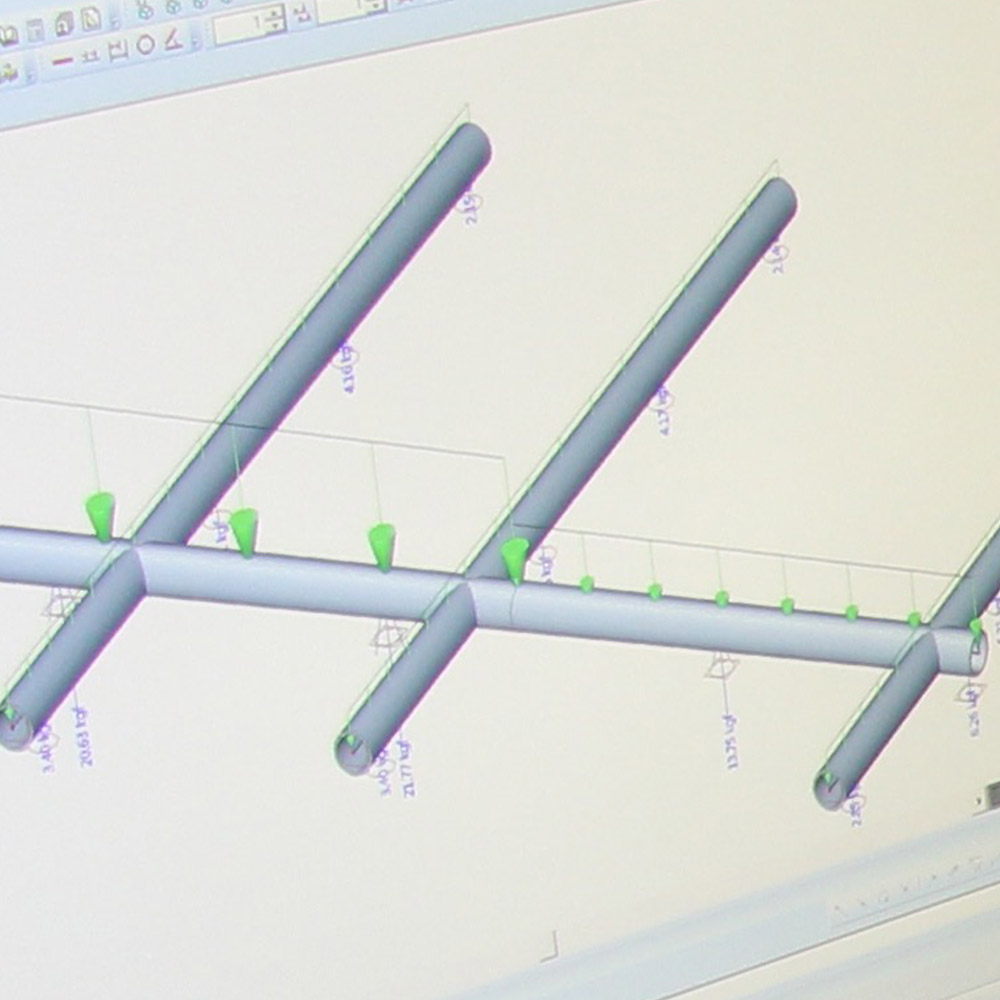

Catenary systems can impose loads on building structures far in excess of the vertical loads applied to each free span. It’s for this reason that Polyplas International’s technical services team offers computer modelled catenary tension analyses to determine both final catenary sag and more importantly, anchor point loading.

This ensures that all catenary systems installed meet the requirements of the structural engineer.

Seismic Bracing & Blast Protection Systems

Gripple seismic bracing systems are globally recognised as industry leading solutions for seismic bracing and blast protection.

The systems are fully tested, industry proven, and designed to be in compliance with AS1170.4, NZ4219 and NZS 1170.5.

The seismic products are also approved to the following and recognised as the most demanding requirement in the world;

- ANSI/ASHRAE 171 Tested

- AC-156 Shaker Table Tested

- AS 1170.0

- OSHPD OPA 2123-10 approved range also available

- SMACNA verified

- UL tested for NEBS GR 63 Core

Time Savings

Gripple seismic bracing products per engineering calculations, including:

Site surveys, on-site pull testing to verify substrate suitability, progress reports and completion certificates can all be requested from Polyplas International Technical Services. Training is also available on a range of Gripple products and time saving installation methods.

Calculations

Engineered seismic bracing calculations based on design category, occupancy, importance and relevant site specific seismic specifications.

Consultant / Contractor

Detailed engineered drawings (submitted by the consultant/contractor) indicating the location of seismic bracing points and bracket type.

Consultant / Contractor

On-site training on seismic product installation.

Correct Installation

Completion visit by a Polyplas International representative to ensure correct installation.

BIM (Building Information Modeling)

This highly collaborative way of working is fast becoming the preferred method for carrying out progressive private sector projects.

Polyplas International’s technical services department can offer full BIM support in the form of 3D model families.

This allows designers to add both fixed and suspended supports for building services, and carry out clash detection in the virtual project environment.

Models are available in a range of file formats including .rfa, .ifc and .dwg and offer full connectivity to product data which can be used to aid cost management, construction collaboration and facilities management.

Detailed component schedules can be created meaning only the correct quantity of product is ordered, minimising cost and waste.

Contact Polyplas International for the latest BIM models.

Embodied CO2 Assessment

Polyplas International recognises that today’s buildings need to be designed to the highest environmental standards.

In order to facilitate this, Polyplas International’s technical services department is able to provide calculations, based on drawing submissions or site surveys, to determine the ECO2 savings when switching to lightweight wire rope suspension systems.

Why use Gripple?

Approvals & Certifications

Gripple holds the following industry approvals for our Wire Bracing Systems:

Case Studies

Suspended Acoustic Panels: Smart, Stylish and Flexible

Wire suspension offers a low-profile, efficient solution for installing acoustic panels in showrooms, combining effective…

Christmas Closure

Office & Warehouse Holiday Hours We close at 2pm Friday 19 December, last dispatch at…