Polyplas International’s technical services department is able to work in collaboration with partners around the world to offer the following range of engineering services to building services consultants, designers and engineers.

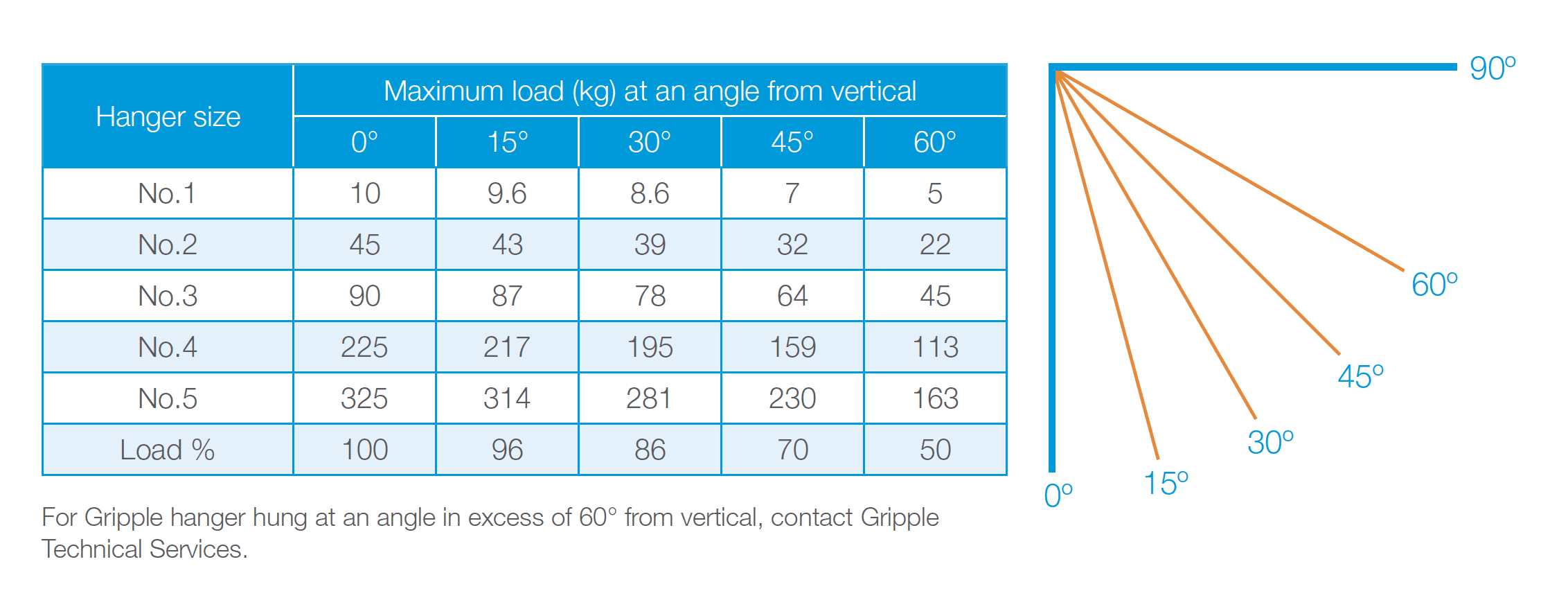

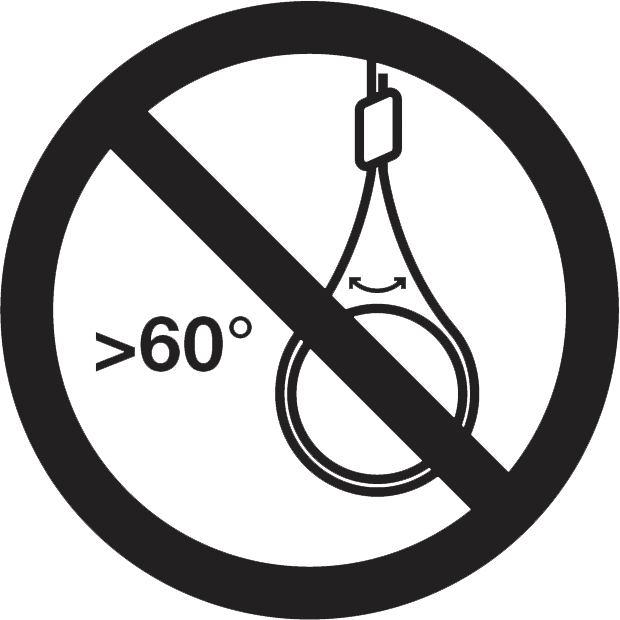

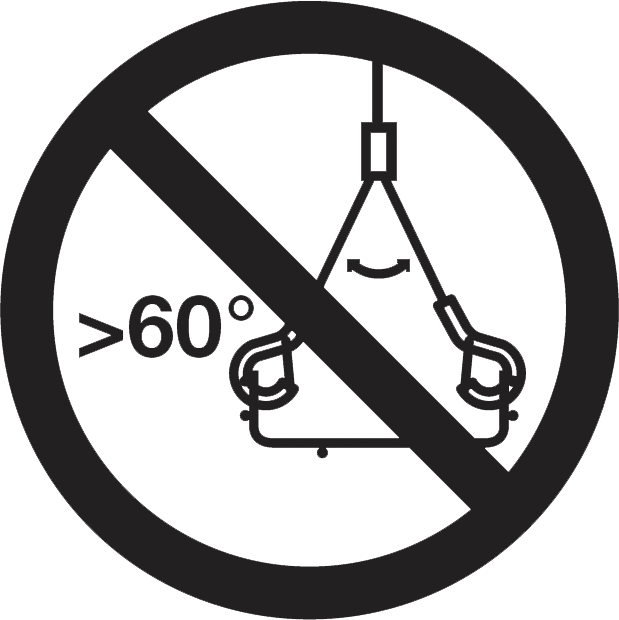

Hanging at Angles

Safe Work Loads

Each size range of Gripple hangers has a specification which must be adhered to in order to ensure safe operation. When suspending vertically, the maximum load rating for each size range is shown in the table below.

If the wire rope is at an angle, an additional sideways force is applied which increases the load on the suspension. The net effect is shown in the table.

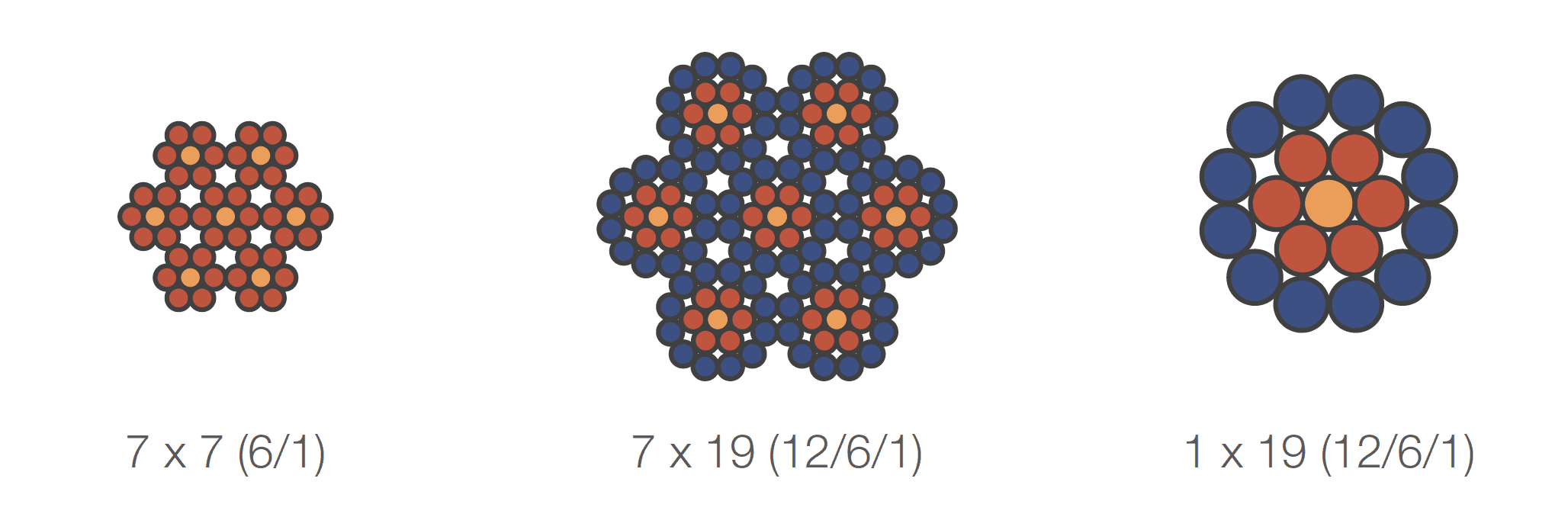

Wire Rope Construction & Cross Sections

The wire ropes used within our product ranges are manufactured with a galvanised coating in accordance with the norm EN 12385.

Key Recommendations

Failure to comply with these recommendations may result in product malfunction and possible damage to property or person and will invalidate the Gripple guarantee. Gripple products are guaranteed to be free from defects in materials and workmanship in accordance with our terms and conditions. No other warranty, whether express or implied, including any warranty of merchantability or fitness for purpose shall exist in connection with the sale or use of any Gripple product.

Full technical information and installation instructions should be obtained directly from Gripple Limited, Gripple Europe or Gripple Inc., any regional Gripple office, or via www.grippleaustralia.com.au.

Please adhere to the following key recommendations:

Always operate the product within its stated safe working load range.

Gripple holds the following industry approvals for our Wire Bracing Systems:

Ensure that the load calculation considers the effect of ‘side load’. For example, at an angle of 60° to vertical the SWL is effectively reduced by 50%

If there is potential for impact on the wire rope suspension or suspended services, seek advice from Gripple Ltd. Technical Services prior to installation.

When installing included angle teardrop hangers on round/spiral ducting or pipes, the final included angle of the assembly should not exceed 60°.

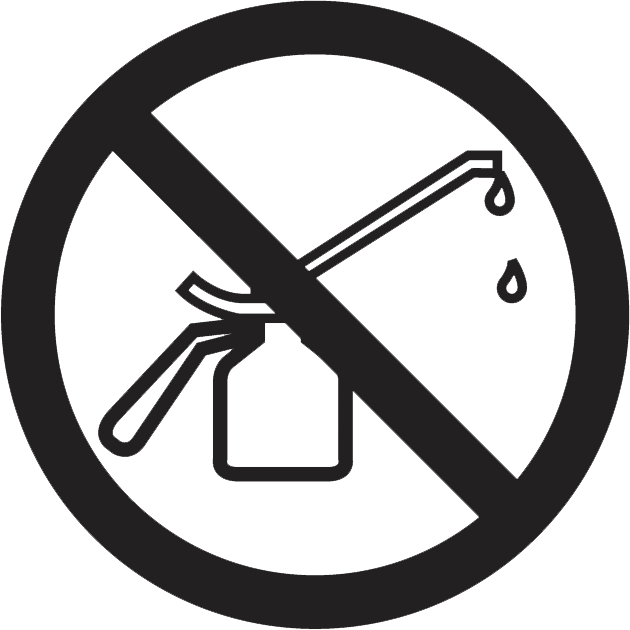

Do not apply oil or any other lubricant to the hanger or any other part of the assembly.

Legs on Y-Fit not to be installed greater than 60°.

Always use the fastener supplied and specified wire rope. Never use on coated wire rope or other rope. Trim any damaged filaments with the wire cutter before use.

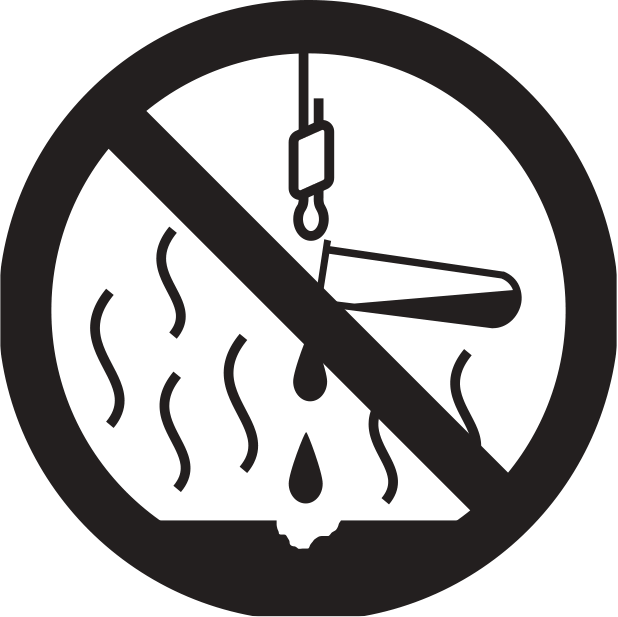

Do not use in chlorinated or chemically corrosive atmospheres. Standard hangers are for use in dry and air conditioned environments only. Stainless steel hangers should be considered for high to saturated humid environments after validation by a competent person. Not suitable for swimming pools.

Do not walk or stand on the Gripple product installation unless expressly designed for this purpose.

Not suitable for swimming pools.

Do not paint the hanger prior to installation. Ensure that the hanger is in its final position prior to applying any paint to the wire rope assembly. Do not move the fastener after painting.

Never join two ends together in-line.

Do not store the product outdoors.

Always use the Gripple hanger with the specified wire rope supplied by Gripple. Gripple products should only be used with products supplied by Gripple and the warranty will not apply if our products are used with any products supplied by third parties.

Do not repair, modify or re-use Gripple products. If you have any queries regarding product performance, please contact sales@gripple.net.au

Quality & Approval

Gripple UK is ISO 9001:2015 and ISO 14001 certified.

Gripple products meet the highest standards of quality with lowest environmental impact.

Gripple’s policy is one of continuous development and innovation. We therefore reserve the right to alter specifications, etc. without notice

Case Studies

All-Energy Australia 2024

Come visit Gripple at stand HH130 to see our range of above ground solar cable…

Bank of New Zealand

Where: Nationwide throughout New Zealand What: Electrical, Mechanical, Fire, Plumbing, Security Seismic Restraints